Structural Steel Fabricators

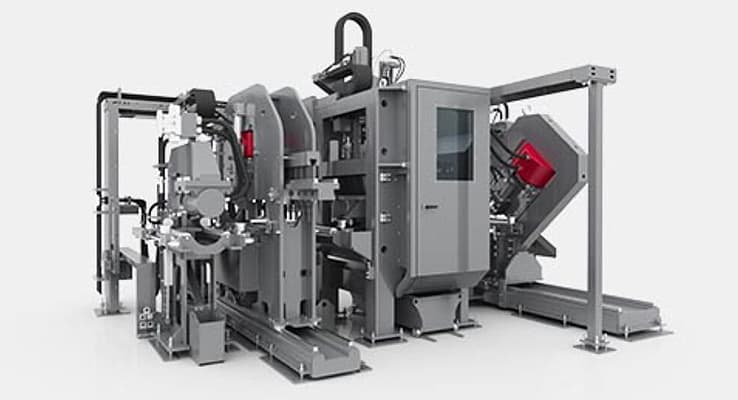

Gulf States Saw & Machine Company sells modular Fusion Arc welding cell, in-house training courses, an abundance of consumables, and robotic welding parts. Instructors are both certified welding and applications engineers.